About MHS LLC

In the past, the typical way to accomplish this task would be to use ground-based aerial work platforms such as scissor lifts or articulating man lifts. These lift platforms would move around the plane itself while operators sprayed the blast media. But this approach came with its own problems. Jack Hinsdale, owner of Material Handling Solutions (MHS) based in Duncan, SC, explains: “This was very time consuming and required a certain amount of clear floor space in order for the lifts to access the perimeter of the planes.”

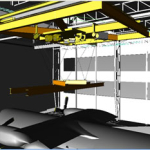

So, instead of using the traditional man scissor lifts that operated from the floor, UST and MHS worked to develop a method that would instead allow for either a manned platform, or a cab fixed with a spray nozzle, to be carried around the plane. This platform, called the Aerial Multi-access Platform, or AMP, is suspended by an overhead crane, and in turn gives the operator complete access to every part of the aircraft. The original concept and design for the AMP was inspired by the Stewart platform that is used in airplane simulators. MHS’ Hinsdale says, “The Stewart platform uses three pair of cylinders underneath a platform and mounted to a base. The tops of the three pairs of cylinders are affixed in an equilateral triangular pattern to the upper platform with the bottoms of the cylinders mounted on the base rotated 60 degrees from the upper platform triangle, thus raising and/or lowering the cylinders in various measures allow the upper platform to be moved on multiple axes. Since three points determine a plane geometrically speaking, the pitch, yaw, and roll achieved in flight is easily simulated.”

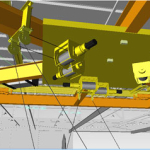

Custom Overhead Crane SystemUST’s design for the paint stripping cab or platform is inverted from the typical Stewart platform, using hoists to lift and lower simultaneously from three separate points. Hinsdale says, “Instead of using cylinders as with the Stewart platform, the AMP system uses six wire rope hoists positioned in the same triangular configuration.”

With the AMP design, and a cab or platform fitted to allow operators to blast media at the plane, the customer can do away with work platforms that take up space on the busy plant floor. Hinsdale says, “The operator can literally fly from the cables in the cab or on a platform, around the plane, blasting media.” Supporting an operator demonstrated the complete flexibility of the AMP concept, and even inspired its application to heavier loads. At Robins AFB in Warner Robins, GA, a key task on the base is to remove and replace the wing boxes from C-130 aircraft. Hinsdale says, “The specific problem with the wing box was the need to pitch, yaw, and/or roll the wing box slightly to allow for easy insertion or removal from the fuselage.”

“The method used for many years was to use an overhead crane or a mobile crane, and rig it to the load as best possible. This was explained to us as a very dicey operation. It was not uncommon for the wing box to be in a bind with the fuselage. The unbinding of this was achieved by lifting, lowering, hammering, or better described as “jimmying” the wing box free or into place.” Once this problem was identified, the AMP system was recognized as having potential to be the perfect solution. It was at this point that UST and MHS partnered for the first application of the AMP concept in the area of materials handling. More specifically, this would be the first application to use the AMP system’s attributes to lift and control an actual load itself, as opposed to its previous blast media applications.

“By using these (AMP) principles to handle an actual product (the wing box), you create the ability for controlled multi-axis movement of t

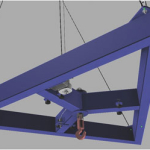

he load itself. In the wing box application, the six hoists are attached to a lower triangular frame that is used to pick up the wing box”, continued Hinsdale. “So in addition to the standard up, down, left, right, forward, and reverse The benefits were soon a movements of the crane, you gain the motions of pitch, yaw, and roll of the load, as with the Stewart platform or the original AMP applications. The wing box system was further enhanced by adding 360 degree rotation to the lower lifting fixture.” parent. Hinsdale says, “Even the very first time they used the system there were measurable improvements on speed, quality, and safety. When you are given the ability to pitch, yaw, or roll an item (in a controlled fashion) when assembling it to another item, you gain a considerable advantage.”

The Systems Design Concept

- AMP is comprised of an upper platform and lower platform.

- Upper platform is composed of 6 winches attached to the trolley frame. Winches will be placed in an equilateral triangle configuration.

- Lower platform is a fixture that will be connected directly to the center wing box to facilitate lift

- Lower platform will also exhibit pitch, roll, and yaw improving precision of CWB placement.

- Lifting frame displays full 360 degree rotation both CCW/CW.

- Lower platform and upper platform will interface with wire ropes.

- A conventional hook can be employed to utilize AMP as an overhead crane.

- System is operated by a belly box control.

The Systems Design Constraints

- Wing box working weight is assumed to be 9120LBF.

- Wing box will be broken lose from fuselage.

- USTS supplied winches will each have a capacity of 6000LBF.

- AMP module must be able to traverse all 3 aircraft bays in BLDG 110E.

Our Clients Include

Contact Us

Shipping Address:

106 Old Dominion Rd.

Duncan, SC 29334

Phone & Fax

PH: 1-864-848-2147

FAX: 1-864-848-3419

Mailing Address:

PO Box 5023 Greenville, SC 29606